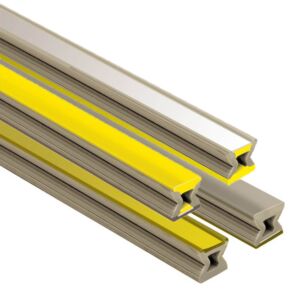

Schluter SCHIENE-STEP Aluminum Stair Nose Tile Edging Trim - 8 ft. 2-1/2 in.

Brand: Schluter

Availability: Ships from Factory (More Info)

Shipping: $49.95 Flat rate ground shipping for unlimited Schluter products in this order. Some exclusions apply.(More Info)

Schluter SCHIENE-STEP is a finishing and edging profile for ceramic tile and natural stone installations on countertops, stairs, and tile over tile applications on walls. The profile features a trapezoid-perforated anchoring leg, which is secured in the mortar bond coat beneath the tile. The top of the profile features a vertical wall section that finishes and protects the tile from damage, while the vertical leg covers the edge of the subassembly, top of the riser, or existing wall tile edge.

SCHIENE-STEP is available in anodized aluminum and brushed stainless steel versions, which have different shapes and intended uses. The stainless steel version is available in three vertical leg lengths: 1-1/2" (39 mm) for countertops, 1-3/16" (30 mm) for stairs, and 7/16" (11 mm) for tile over tile applications. Matching inside and outside corners and connectors are available, depending on the vertical leg length. The anodized aluminum version is intended for residential stair applications (stairs not exposed to heavy traffic). It is available in two vertical leg lengths, 1-3/16" (30 mm) and 1-1/2" (39 mm), to cover the edge of the sub-assembly. The integrated joint spacer establishes a defined joint cavity between the tile and the profile. Accessories are not available for the anodized aluminum version.

Schluter SCHIENE-STEP Features:

- Prevents tile edges from chipping

- The ribbed vertical leg covers the edge of the countertop sub-assembly or the top of the stair riser

- Integrated joint spacer establishes a defined joint cavity between the tile and the profile (anodized aluminum version only)

- The “T” configuration of the profile effectively finishes and protects the edges of both the old and new tile on walls

- Ideal for residential applications

- 90° and 135° inside and outside corners, connectors, and end caps available in brushed stainless steel only

- Available in anodized aluminum and brushed stainless steel

Schluter Edging Trim Installation

- Select the profile according to tile thickness and format.

- Using a notched trowel, apply thin-set mortar to the area where the profile is to be placed. If the JOLLY, QUADEC, RONDEC, RONDEC-DB, DECO-DE, FINEC, or FINECSQ profile is to be used as edging for an outside wall corner, finish tiling one wall first; then trowel thin-set mortar over the corner area of the second wall.

- Press the perforated anchoring leg of the profile into the mortar and align.

- Trowel additional thin-set mortar over the perforated anchoring leg to ensure full coverage and support of the tile edges.

- Solidly embed the tiles so that the tiled surface is flush with the top of the profile; the profile should not be higher than the tiled surface, but rather up to approx. 1/32" (1 mm) lower.

- Set the tile to the integrated joint spacer, which ensures a uniform joint of 1/16" - 1/8" (1.5 - 3 mm). With the stainless steel profiles, leave a space of approximately 1/16" - 1/8" (1.5 - 3 mm).

- Fill the joint completely with grout or setting material.

- Work with materials and tools that will not scratch or damage sensitive surfaces. Setting materials must be removed immediately, especially from aluminum.

Note: Matching corners and connectors are available. Corners are held in place with thin-set mortar. Fill the ends of the profile with thin-set mortar prior to inserting the accessories. Connectors are held in place with a friction fit. Insert the connector into the profile approximately half the length of the connector piece and connect the adjacent profile.

How do I cut profiles?

Schluter™ profiles are available in a variety of different materials , so methods for cutting vary. Below are best practices for cutting according to material type.

Plastic

Plastic profiles may be cut using Schluter™-SNIPS or similar. It is important to make sure the blade is sharp in order to ensure a clean cut.

Aluminum

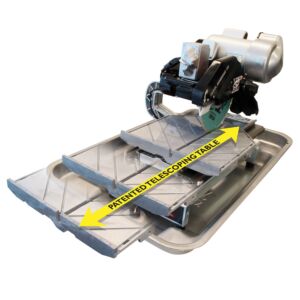

One option for cutting aluminum profiles is to simply use a hacksaw. Look for a bimetal blade and select the highest teeth per inch, or TPI, available. A miter box is recommended to help ensure a straight cut. Aluminum profiles may also be cut using a variable-speed angle grinder with the Schluter-PROCUT-TSM cutting wheel. Set the angle grinder to the lowest speed. A clamp or cutting jig can be used to secure the profile and help ensure a straight, clean cut. Finally, aluminum profiles can also be cut using a chop saw or miter saw with a non-ferrous blade. After cutting, make sure to remove any burs with a file before installation.

Brass

Brass profiles can be cut by using a hacksaw with a bimetal blade with the highest teeth per inch available, or by using a chop saw or miter saw with a non-ferrous blade. Removing any burrs from the cut end of the profile with a file (or similar) is also recommended.

Stainless Steel

The simplest option for cutting stainless steel is to use a variable-speed angle grinder with the Schluter-PROCUT-TSM cutting wheel. Set the angle grinder to the lowest speed. Another option for cutting stainless steel profiles is to use a band saw with a metal cutting blade. After cutting, make sure to remove any burs with a file before installation.

| SKU | S SCHIENE-STEP A |

|---|---|

| Weight (lbs.) | 1.49 - 1.84 |

| Non-Returnable | No |

| Manufacturer | Schluter |

| Warranty | 5 Year Limited Warranty |

| Dimensions (L x W x H) | 8' 2-1/2" x 1-1/2" - 8' 2-1/2" x 2-1/16" |

| Trim Material | Aluminum |

| Trim Length | 8' 2-1/2" |