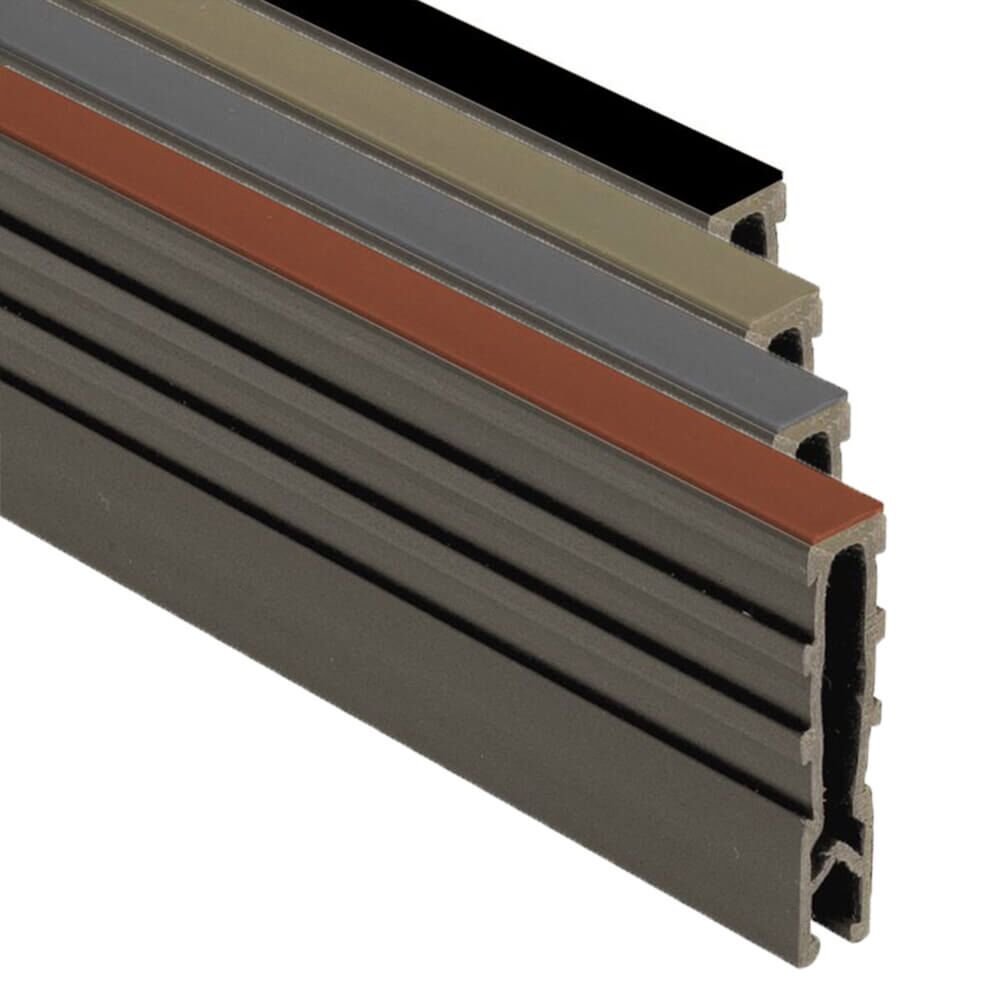

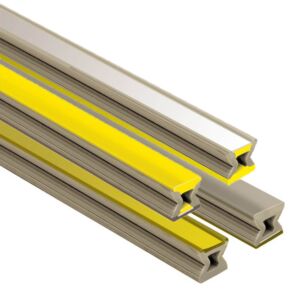

Schluter DILEX-MP 5/16" PVC Screed Joint Tile Edging Trim - 8 ft. 2-1/2 in.

Brand: Schluter

Availability: Ships from Factory (More Info)

Shipping: $49.95 Flat rate ground shipping for unlimited Schluter products in this order. Some exclusions apply.(More Info)

Schluter-DILEX-MP is a screed joint profile with rigid PVC side sections that protect tile edges and a soft chlorinated polyethylene (CPE) movement zone that separates individual fields in the tile assembly and forms the visible surface.

Schluter DILEX screed joint profiles are designed to provide movement joints in tile installations that are set in a mortar bed (e.g., ceramic tile, natural stone, pavers, and agglomerate tile). These profile systems are placed to produce individual fields in the assembly and feature flexible central zones to accommodate movement. DILEX mortar bed joint profiles may also be inserted in saw-cut joints or wider joints; for example, in the case of renovations. The remaining joint between the tile and the profile must be filled completely with grout or epoxy. The side sections of the profiles, made of rigid PVC, protect the edges of the adjacent covering against mechanical stresses caused by industrial traffic. However, where heavy mechanical stresses are anticipated, limitations of the PVC as edge protection must be considered.

Schluter DILEX-MP adjusts to the thickness of the mortar bed and tile surface by attaching the DILEX-MPV extensions. The profile features a central movement zone made of soft chlorinated polyethylene (CPE), which overlaps the recycled rigid PVC side sections by approximately 1/32" (1 mm), thus providing a more aesthetically pleasing exposed surface when compared to DILEX-MOP.

- Designed to allow movement and reduce stress in large, tiled areas

- Eliminates the need for caulking

- Prevents cracking and delamination of tiles

- Provides movement joints in tile installations that are set in a mortar bed

- Ideal for ceramic tile, natural stone, pavers, and agglomerate tile

Schluter Edging Trim Installation

- Select the profile height according to the height of the assembly.

- Set the profile flush against the edge area of an already completed field. The profile must be completely embedded laterally.

- Install tiles for the adjacent field flush to the profile surface. The profile must be completely embedded laterally.

- Fill the remaining joint between the profile and the covering completely with grout or setting material. Installation note on joint repair: Prepare the joint’s width and depth appropriately and insert profile into joint. Fill joint space between profile and covering completely with grout, epoxy, or thin-set mortar.

Note: Matching corners and connectors are available. Corners are held in place with thin-set mortar. Fill the ends of the profile with thin-set mortar prior to inserting the accessories. Connectors are held in place with a friction fit. Insert the connector into the profile approximately half the length of the connector piece and connect the adjacent profile.

How do I cut profiles?

Schluter™ profiles are available in a variety of different materials , so methods for cutting vary. Below are best practices for cutting according to material type.

Plastic

Plastic profiles may be cut using Schluter™-SNIPS or similar. It is important to make sure the blade is sharp in order to ensure a clean cut.

Aluminum

One option for cutting aluminum profiles is to simply use a hacksaw. Look for a bimetal blade and select the highest teeth per inch, or TPI, available. A miter box is recommended to help ensure a straight cut. Aluminum profiles may also be cut using a variable-speed angle grinder with the Schluter-PROCUT-TSM cutting wheel. Set the angle grinder to the lowest speed. A clamp or cutting jig can be used to secure the profile and help ensure a straight, clean cut. Finally, aluminum profiles can also be cut using a chop saw or miter saw with a non-ferrous blade. After cutting, make sure to remove any burs with a file before installation.

Brass

Brass profiles can be cut by using a hacksaw with a bimetal blade with the highest teeth per inch available, or by using a chop saw or miter saw with a non-ferrous blade. Removing any burrs from the cut end of the profile with a file (or similar) is also recommended.

Stainless Steel

The simplest option for cutting stainless steel is to use a variable-speed angle grinder with the Schluter-PROCUT-TSM cutting wheel. Set the angle grinder to the lowest speed. Another option for cutting stainless steel profiles is to use a band saw with a metal cutting blade. After cutting, make sure to remove any burs with a file before installation.

| SKU | S DILEX MP |

|---|---|

| Weight (lbs.) | 0.74 |

| Non-Returnable | No |

| Manufacturer | Schluter |

| Warranty | 5 Year Limited Warranty |

| Dimensions (L x W x H) | 8' 2-1/2" x 5/16" x 1 3/8" |

| Trim Material | PVC |

| Trim Length | 8' 2-1/2" |